ReGrow Timber Canopy

The ReGrow Timber Canopy built for the Bundesgartenschau Mannheim 2023 combines the natural materials timber and flax to showcase the use of sustainably sourced materials in architecture and to reflect on the future of the construction industry. The project, a collaboration between the professorships Design of Structures (dos) and Digital Design and Fabrication (DDF) at the Karlsruhe Institute of Technology (KIT) together with industry partner FibR GmbH, is enabled by a combination of fast regrowing natural materials together with advanced digital planning and fabrication technology. The canopy consists of three interconnected timber sections arranged in a hexagonal pattern, each supported by a column made of robotically wound flax fibres. Owing to the rhomboidal shape of the timber elements, the roof and column system is modularly extensible in any direction. The organised layout of the canopies in plan is counterbalanced by their double curvature, a main feature introduced to increase the stiffness and load-bearing capacity of the structural system on the base of its geometry.

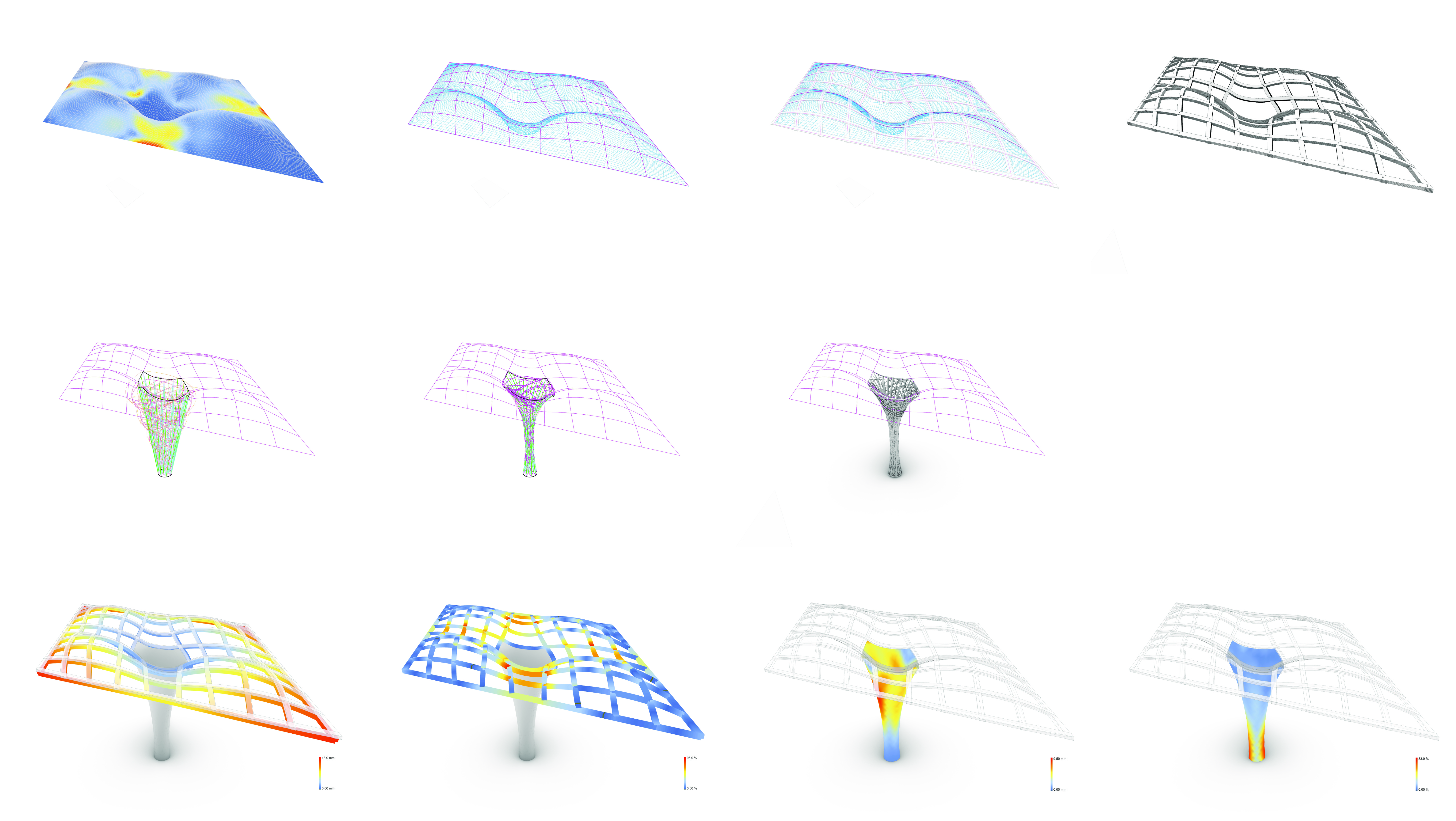

The design of the timber roofs is based on current research on how adhesive-free curved timber structures can be constructed by means of elastic bending and mechanical lamination. Each roof is built up by nine layers of initially flat 6 x 80 mm silver fir laths, successively bent in shape and joined together with a bolt at their intersection points. The precise placement and alignment of the bolts guides the construction of the roof and freezes the geometry in the initially planned position. The guiding curves of the timber laths are based on a geodesic pattern to ensure planarity in the overlaps. This is essential to create the continuous and smooth surface necessary to be able to couple the lamellas together to form the load-bearing cross-section.

Revisited construction principles of double curved timber structures

It is well known that form and curvature play an important role in the design of material efficient structural systems. However, in timber construction, fabricating curved elements proves to be a difficult and wasteful task, which often requires extensive moulding, and machining, pressing and gluing. To avoid these efforts in the construction of the ReGrow Timber Canopy, elastic bending of initially flat timber laths was used to create the final shape and induce the planned curvature in the roof elements. The scaling of actively bent systems has been shown to have strong structural limitations, and they are therefore rarely seen in large-scale architectural contexts, confining their application to small-scale demonstrators. The Canopy aims at showcasing the potential of these systems for large-scale structural applications by employing elastic bending primarily as a form-giving and manufacturing strategy. The structural limitations are overcome by arranging individually bent lamellas in several superposed layers, to obtain a multi-layered beam with sufficient cross-sectional properties to assure the necessary structural capacity.

Designing with natural uncertainties

Naturally grown materials are highly inhomogeneous in size and shape and their mechanical properties are often unpredictable. In timber construction, these difficulties have been overcome through the development of engineered wood products (EWPs), which are typically fabricated through the chemical bonding of multiple layers of lumber. Although providing a structurally efficient bond, the use of synthetic adhesives degrades the sustainability and recyclability of the timber, To improve the environmental performance of the timber roofs, the structural bond between the lamellas was achieved through mechanical lamination. Conventional mechanically laminated timber uses steel nails or steel screws to join multiple layers of timber, to create larger and stronger sections. However, for the construction of the ReGrow Timber Canopy, the mechanical bond was established by nailing the individual layers together using beech wood nails, a traditional fastener re-engineered to meet the demands of modern, sustainable construction. Through the heat generated by friction when the nail is shot into the wood, the lignin of the wooden nail melts and welds to the surrounding wood to create a strong bond completely free from chemicals. This showcases an alternative to glued laminated timber for creating spatially complex but structurally efficient timber structures.

Robotic coreless filament winding

Extending the research on naturally sourced materials for building construction, the columns of the ReGrow Canopy consist of renewable flax fibres manufactured through Core-less filament winding (CFW), a recent fabrication technique that enables the production of structural elements out of fibre-based materials in an additive winding process. By pulling the fibre strands in a resin bath, the flax fibres get impregnated in a polymer matrix while being wound around pins attached to a reusable steel frame. The polymer matrix is essential to protect the fibres against environmental influences but also to give the generated fibre composite material its excellent mechanical properties. The specific winding sequence and the interaction of the fibre strands generates the unique column design with a high degree of double curvature. This fabrication method thus produces a load-bearing column that through the combination of material properties and form gets its exceptional load-bearing capacity, while at the same time being extremely lightweight. In a further processing step, the polymer matrix is cured in an oven, giving the biobased material its full strength and dimensional stability. After demoulding, the winding frame can be reused for the production of the next column, resulting in a very low material input production sequence underlined by the almost waste-free processing of the flax fibres. The three 2.8m high columns weigh around 42 kg each and can withstand a compressive load of over 3.5 t. Thanks to their extreme lightness, the columns can be easily transported and mounted with minimal effort.

Natural resources for the future of construction

The ReGrow Timber Canopy showcases the potential use of naturally sourced materials in design and construction by leveraging digital technologies and advanced manufacturing. The Canopy serves as a platform to explore the use of renewable building materials and circularity in construction combined with digital manufacturing processes, addressing the environmental and societal obstacles that the built environment is currently facing.

Gallery

Project Partners

Professorship Digital Design and Fabrication (DDF)

Tenure-Track Prof. Moritz Dörstelmann, M.Sc. Daniel Fischer, M.Sc. Javier Fuentes Quijano

Professorship Design of Structures (dos)

Prof. Dr.-Ing. Riccardo La Magna, M.Sc. David Andersson Largueche, M.Sc. Michael Kalkbrenner

Professur Bauphysik & Technischer Ausbau (fbta)

Prof. Andreas Wagner, M.Sc. Rafael Bartsch

Institut für Industriebetriebslehre und Industrielle Produktion (IIP)

Dr. Rebekka Volk, M.Sc. Simon Steffl (IIP)

„Next Generation Photovoltaics“ am Lichttechnischen Institut (LTI)

Tenure-Track Prof. Dr. Ulrich W. Paetzold, Simon Ternes

FibR GmbH

Dr.-Ing. Julian Fial, Puree Srisuk

Student support

Nicolò Giovanella, Marco Tarrio Torres, Leon Vandreike

WITH SUPPORT OF

Schorn & Groh

Helber + Ruff

Beck Fastening

Bächer Bergmann GmbH

PHOTOGRAPHER

Tobias Wootton

RESEARCH FUNDING

ReGrow is funded by the Baden-Württemberg Ministry of Food, Rural Areas and Consumer Protection (MLR) as part of the Bioeconomy Innovation Programme for Rural Areas in the field of sustainable construction with regionally renewable raw materials and digital planning and manufacturing processes.