ReGrow Willow

The construction industry depends heavily on finite resources and follows a linear economic model of take-make-waste, causing significant environmental degradation through resource depletion and waste generation. Introducing alternative material cycles in construction could provide a solution to this challenge by enabling closed material loops, minimising waste and diversifying material sources.

The research demonstrator ReGrow Willow presents an earth-willow hybrid structure for architectural and construction applications that enables circular material cycles through bespoke digital fabrication systems and computational tools.

Earth-willow Construction System

Expanding on the previous research conducted by the Professur Digital Design and Fabrication (DDF) and the Professur design of structures (dos) at the Karlsruhe Institute of Technology, which reimagined the traditional wattle and daub material system and resulted in the project InterTwig, ReGrow Willow presents an innovative resource stream. Willow, a rapidly renewable bio-based material, can be composted at the end of its life cycle, while earth remains infinitely recyclable without loss of value. Building upon this foundation, the project aims to develop a comprehensive construction system. Through the development of customised fabrication processes, the project demonstrates the potential widespread use of prefabricated building elements made from willow and earth. The synergistic combination of these two materials, with willow serving as tension reinforcement for the earth, is advanced through tailored computational workflows. Additionally, integrative digital design tools manage the interdependencies between architectural design, material systems, structural performance, and fabrication processes.

Digital Fabrication & Computational Design

Building with bio-based materials like willow poses challenges due to their inherent variability. Therefore, the project emphasizes the co-evolution of the material system and the fabrication process. To achieve this, a comprehensive fabrication system is developed, starting with a two-axis machine capable of extruding and depositing continuous macro-fibres made from spliced willow branches using additive techniques. Controlling the machine's extrusion, movement, and deposition path proves challenging due to factors such as the flexibility and varying thickness of willow branches, as well as the requirement for tensioning in the final components.

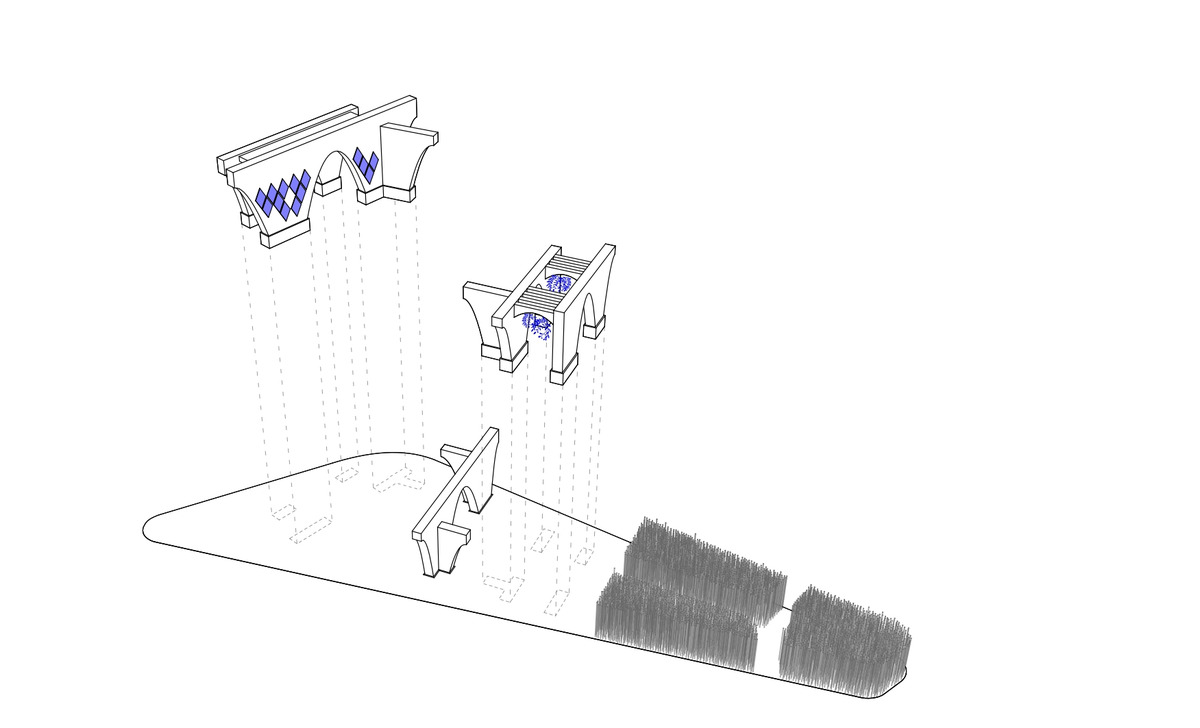

The fabrication process allows the creation of morphologically differentiated components that adapt to the overall design, incorporating adaptive weaving and material placement based on local requirements and structural performance. Willow components are used for their tensile strength and simultaneously serve as formwork and reinforcement for waste-free and material-efficient earth construction. The earth is shot into selected cells within the willow formwork using a modified plastering machine that employs high-pressure pneumatic extrusion. The geometry of the willow formwork allows for seamless integration with the earth, eliminating the necessity for any additives or adhesives.

The research also uses structural principles as a guiding factor for the development of the material system and employs an integrative co-design approach to manage the reciprocal relationships between structural performance, material system behaviour and fabrication processes. Digital studies of mechanical properties and computational analyses inform the distribution, orientation, and gradation of the materials.

The Research Demonstrator at BUGA 2023

Situated within the exhibition area Erlebnisraum Bioökonomie at the Federal Horticultural Show (BUGA) 2023 in Mannheim, ReGrow Willow incorporates concepts of microclimatic adaptation and local energy harvesting, that serve to exemplify a holistic transition towards establishing a sustainable built environment.

The first section of the demonstrator was constructed in April 2023, with further expansion planned until August 2023. Currently, the installation consists of 19 prefabricated components weighing between 25 and 500 kg. These components integrate a joinery system for inter-component and assembly connections. The structure, assembled in two days, incorporates design-for-disassembly concepts to accommodate its temporary use and future extensions. Computational workflows inform the material articulation and distribution, prioritising material efficiency and structural performance, which are also evaluated through physical testing. As a result, a material gradient is achieved, with earth primarily used at the foundations and willow predominating at the top. Two finishing treatments are used to assess weathering impact, an important challenge for earthen construction.

The research has the potential to expand the possibilities and architectural language of earth construction, showcasing a localised approach that harnesses the customisation potential of digital design and fabrication towards the development of digital circular construction.

The research project ReGrow & the Symposium ReGrow - Natural Resources in Digital Circular Construction

The two-year research project ReGrow, funded by the state government and initiated by five professorships of the Karlsruhe Institute of Technology (KIT) - Digital Design & Construction (DDF), Design of Structures (dos), Building Physics & Technical Design (fbta), Light Technology Institute (LTI) and Institute of Industrial Management and Production (IIP) in cooperation with the industry partner FibR GmbH, will be concluded with the symposium "ReGrow - Natural Resources in Digital Circular Construction". The symposium will bring together local and international experts from science and industry on 29.09.2023 at the BUGA in Mannheim to discuss current challenges and opportunities around the use of natural resources such as fibres, wood and earth-based materials in architectural design and robotic manufacturing. It questions current production methods and gives an outlook on digital circular building.

Gallery

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT.jpg)

Project partners

Karlsruhe Institute of Technology - Department of Architecture

Professur Digital Design and Fabrication (DDF)

Tenure-Track Prof. Moritz Dörstelmann, Daniel Fischer, Javier Fuentes, Fanny Kranz, Eszter Olah, Baris Wenzel, Vincent Witt, Erik Zanetti, Mehrdad Zareian

Professur Design of Structures (dos)

Prof. Dr.-Ing. Professor Riccardo La Magna, Gianluca Casalnuovo, Tamara Haußer

Professur Bauphysik & Technischer Ausbau (fbta)

Prof. Andreas Wagner, Rafael Bartsch

Institut für Industriebetriebslehre und Industrielle Produktion (IIP)

Dr. Rebekka Volk, Simon Steffl (IIP)

„Next Generation Photovoltaics“ am Lichttechnischen Institut (LTI)

Tenure-Track Prof. Dr. Ulrich W. Paetzold, Simon Ternes

The project was realised in collaboration with architecture students from the Faculty of Architecture at KIT between October 2022 and July 2023:

Alexander Albiez, Nicolas Bär, Atanaska Chausheva, Philipp Dworatzek, Bedia Erbay, Andrian Frach, Christian Hoffmann, Michael Hosch,Miriam Hosch, Aimée Issaka, Maja Jankov, Nicolas Klemm, Loana Köhler, Kim Krueck, Claudia Lehmann, Christina Müller, Jana Naeve, Simon Rieß, Daniel Sandrock, Isabel Schumm, Lara Sodomann, Johanna Sonner, Yannick Scherle, Andre Schnierle, Sabine Tröger, Ida Vincon, Yifei Wang, Kyra Weis, Niklas Wittig

RESEARCH FUNDING

ReGrow is funded by the Baden-Württemberg Ministry of Food, Rural Areas and Consumer Protection (MLR) as part of the Bioeconomy Innovation Programme for Rural Areas in the field of sustainable construction with regionally renewable raw materials and digital planning and manufacturing processes.

_DDF_dos_KIT_rdax_1240x1860s.jpg)

_DDF_dos_KIT_rdax_1240x827p.jpg)

_DDF_dos_KIT_rdax_1240x877s.jpg)

_DDF_dos_KIT_rdax_1240x931s.jpg)

_DDF_dos_KIT.jpg)

_DDF_dos_KIT_rdax_1240x627p.jpg)

_DDF_dos_KIT_rdax_1240x710p.jpg)

_DDF_dos_KIT_rdax_1240x886p.jpg)

_DDF_dos_KIT_rdax_1240x602p.jpg)

_DDF_dos_KIT_rdax_1240x930p.jpg)